King 5500 Pellet Stove Manual⁚ A Comprehensive Guide

This comprehensive guide serves as a user manual for the King 5500 pellet stove, a popular heating appliance known for its efficiency and reliability. The manual covers a wide range of topics, from safety precautions and installation to operation, maintenance, and troubleshooting. Whether you are a first-time pellet stove owner or a seasoned user, this manual will provide you with all the information you need to safely and effectively use your King 5500 pellet stove.

Introduction

Welcome to the world of efficient and cozy heating with the King 5500 pellet stove. This manual is your comprehensive guide to understanding, operating, and maintaining your new appliance. The King 5500, along with its variants, the 5500M and 5500XL, are renowned for their ability to provide warmth and comfort to homes across North America. Developed by United States Stove Company, a company with a rich history dating back to 1869, these stoves are a testament to quality craftsmanship and innovative heating technology.

Throughout this manual, you will find detailed instructions on every aspect of your King 5500 pellet stove, from initial installation and safety considerations to everyday operation, maintenance procedures, and troubleshooting tips. We encourage you to read this manual thoroughly before installing and using your stove to ensure safe and efficient operation. Your comfort and satisfaction are our top priorities.

Safety Precautions

Your safety and the safety of your home are paramount. Before installing and using your King 5500 pellet stove, carefully read and understand these safety precautions. Failure to follow these instructions could result in property damage, bodily injury, or even death.

Never use your pellet stove as a primary source of heat. It is designed to supplement your existing heating system and should not be relied upon as the sole source of heat for your home. Always maintain a safe distance between the stove and combustible materials, such as furniture, curtains, and walls. Ensure proper ventilation by following the installation guidelines provided in this manual. Never operate the stove with a blocked or restricted vent.

Children and pets should be closely supervised when near the stove. Never leave the stove unattended while in operation. Exercise caution when handling hot surfaces, including the stove’s exterior, door, and vent pipe. Use a heat-resistant glove or tool to avoid burns.

Installation

Proper installation is crucial for safe and efficient operation of your King 5500 pellet stove. This section provides a general overview of the installation process. For detailed instructions, please refer to the installation manual included with your stove. It is highly recommended that you consult with a qualified professional installer for assistance, especially if you are unfamiliar with the installation process.

The installation process involves selecting a suitable location, ensuring adequate clearance from combustible materials, and properly connecting the stove to the vent system. The stove must be installed on a solid, level surface capable of supporting its weight. The vent pipe should be routed directly through the wall or roof, with no horizontal runs exceeding the manufacturer’s specifications. The vent termination should be located above the roofline, and the vent pipe should be securely fastened to prevent drafts and leaks.

Before starting the installation, ensure that you have all the necessary tools, materials, and permits required for the installation in your area. It is essential to follow all local building codes and safety regulations. After completing the installation, a qualified inspector should inspect the stove and vent system to ensure it meets all safety standards;

Operation

Operating your King 5500 pellet stove is straightforward, but it’s essential to follow the instructions in this manual to ensure safe and efficient use. Before starting the stove for the first time, carefully read through the operating instructions and familiarize yourself with the control panel and its functions. The control panel typically includes buttons for ignition, fan speed, temperature settings, and other features.

To start the stove, fill the hopper with high-quality hardwood pellets that comply with the Association of Pellet Fuel Industries standards. Ensure the pellets are dry and free of moisture or impurities. Close the hopper lid tightly to prevent dust and debris from entering the stove. Turn on the power switch and activate the ignition system. The stove will ignite the pellets and begin heating the room.

Use the control panel to adjust the temperature settings to your desired level. The stove will automatically maintain the set temperature by regulating the pellet feed rate and fan speed. Regularly monitor the stove’s operation and ensure the hopper remains filled with pellets. Always follow the safety precautions outlined in this manual and never leave the stove unattended while it is operating.

Maintenance

Regular maintenance is crucial for ensuring the longevity and optimal performance of your King 5500 pellet stove. Following these maintenance guidelines will help prevent issues and ensure safe operation. Begin by cleaning the stove’s ash pan and burn pot regularly, removing accumulated ash and debris. A buildup of ash can hinder airflow and reduce efficiency. Clean the glass door using a stove-specific cleaner to remove soot and maintain visibility of the fire.

Inspect the stove’s exterior for any signs of damage, wear, or rust. Replace any damaged or worn parts promptly. Check the stove’s air intake and exhaust vent for obstructions, ensuring proper airflow. Clean the auger and feed system to prevent clogging and ensure smooth pellet delivery. Inspect the electrical wiring and connections for any loose or damaged components. If you notice any issues, consult the troubleshooting section of this manual or contact a qualified technician.

Perform a thorough cleaning of the stove’s internal components, including the heat exchanger and combustion chamber, at least once a year. This will remove accumulated creosote and ensure optimal heat transfer. It’s recommended to have a qualified professional inspect the stove annually for safety and performance checks.

Troubleshooting

While the King 5500 pellet stove is designed for reliable operation, occasional issues may arise. This section will guide you through troubleshooting common problems. If the stove is not igniting, check if the hopper is full of pellets and the power cord is plugged in. Ensure the door is securely closed, as a loose door can prevent ignition. If the stove is smoking excessively, check for blockages in the vent system or the air intake. A clogged vent can restrict airflow and cause smoke buildup.

If the stove is not producing enough heat, check the settings and adjust the thermostat to a higher temperature. Ensure that the pellets are of good quality and dry, as moist pellets can hinder combustion. If the stove is shutting down unexpectedly, check for a flashing “A” on the display, which indicates a pellet feeding issue. Ensure the door is closed tightly and the hopper is full. If the problem persists, consult the manual or contact a qualified technician.

For other issues, such as a noisy auger, a malfunctioning blower, or a faulty control panel, refer to the troubleshooting section in your King 5500 pellet stove manual. This section provides detailed instructions for diagnosing and resolving various problems. If you are unable to resolve the issue, contact a qualified technician for assistance.

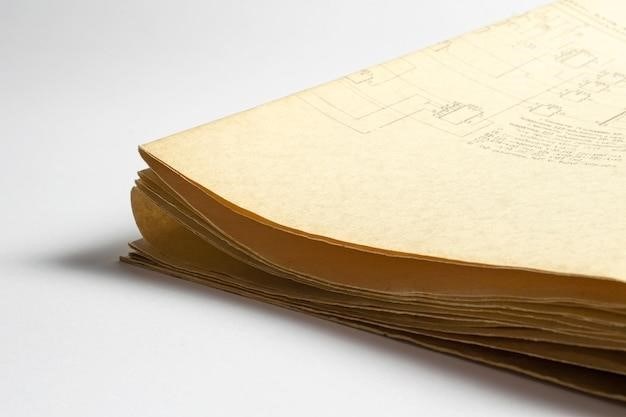

Parts Diagram/List

The Parts Diagram/List section of the King 5500 pellet stove manual provides a visual representation and detailed description of each component of the stove. This comprehensive list helps you identify specific parts for maintenance, repair, or replacement. The diagram typically includes a detailed illustration of the stove, highlighting key components such as the hopper, auger, burn pot, blower, control panel, and vent system. Each component is labelled with a corresponding part number, making it easy to locate the right part when ordering replacements.

The Parts List section provides a detailed description of each part, including its function, material, and dimensions. This information is essential for ordering the correct replacement part and ensuring proper installation. The manual may also include a table or chart that lists common replacement parts, their part numbers, and their estimated price. This can be helpful for budgeting and planning future maintenance or repairs.

Having access to a Parts Diagram/List is essential for maintaining your King 5500 pellet stove. It allows you to identify and order the right parts, ensuring proper functionality and extending the life of your stove. Always refer to the manual for the most accurate and up-to-date parts information.

Wiring Diagram

The Wiring Diagram section of the King 5500 pellet stove manual provides a detailed visual representation of the stove’s electrical system. It’s a crucial resource for understanding the flow of electricity within the stove, identifying individual components, and troubleshooting electrical issues. The diagram typically uses a combination of symbols and lines to illustrate the connection between various components, including the control panel, thermostat, igniter, blower motor, auger motor, and safety sensors.

Each wire is labeled with its corresponding color code, making it easier to identify and trace connections. The diagram might also include a legend that explains the meaning of each symbol used. This visual guide helps you understand how the electrical system operates, allowing you to diagnose potential problems by tracing the flow of electricity from the power source to the various components.

It’s important to remember that working with electrical systems requires caution and expertise. Always consult a qualified electrician if you suspect any electrical issues with your King 5500 pellet stove. The Wiring Diagram is a valuable tool for qualified technicians, providing them with the necessary information to safely repair or troubleshoot electrical problems.

Fuel Considerations

The King 5500 pellet stove is designed to burn premium hardwood pellets that meet specific quality standards. The manual emphasizes the importance of using the right fuel for optimal performance and safety. It outlines key considerations for selecting and storing pellets, ensuring a clean and efficient burn.

The manual typically recommends pellets that meet the Association of Pellet Fuel Industries (APFI) standards. These standards ensure pellets are made from high-quality hardwood, with a consistent density, moisture content, and size. The manual might also specify a minimum density requirement, typically around 40 pounds per cubic foot.

The manual also provides guidance on storing pellets to prevent moisture absorption and degradation. Proper storage involves keeping pellets in a dry, well-ventilated area, preferably in sealed bags or containers. By following these fuel considerations, you can maximize the efficiency of your King 5500 pellet stove, ensure a clean burn, and minimize potential issues related to poor fuel quality.

Electrical Specifications

The King 5500 pellet stove requires a standard electrical connection for operation. The manual provides detailed electrical specifications to ensure proper installation and safe use. It typically outlines the voltage, amperage, and frequency requirements for the stove.

Commonly, the King 5500 operates on a standard 110-120 volt, 60 Hz electrical supply. The manual might also specify the amperage draw, which is typically around 3.0 amps. The manual may include information about the wattage requirements, which can vary slightly depending on the specific model.

It’s crucial to ensure that the electrical outlet you use is compatible with the stove’s specifications and that the wiring is properly installed and grounded to prevent electrical hazards. The manual might also recommend consulting a qualified electrician for any questions or concerns regarding electrical installation or troubleshooting.

Environmental Impact

The King 5500 pellet stove is designed to be an environmentally friendly heating option. It burns wood pellets, a renewable fuel source derived from wood waste, reducing reliance on fossil fuels. The manual emphasizes the stove’s compliance with EPA emission standards, highlighting its contribution to cleaner air quality.

The stove’s efficiency in burning wood pellets minimizes particulate matter and other pollutants released into the atmosphere. The manual might also mention the stove’s low ash content, which reduces the need for frequent ash removal and minimizes waste.

The manual may also include information about the stove’s carbon footprint, comparing it to other heating options. By burning renewable fuel and adhering to emission standards, the King 5500 pellet stove promotes a sustainable and environmentally conscious approach to home heating.

Warranty Information

The King 5500 pellet stove comes with a manufacturer’s warranty that covers defects in materials and workmanship. The warranty period typically lasts for a specific timeframe, such as one or two years, and may vary depending on the specific model or components. The manual will clearly outline the warranty coverage, including the duration, specific parts covered, and any exclusions.

It is crucial to register your stove with the manufacturer within a specified timeframe after purchase to activate the warranty. The manual will provide instructions on how to register your stove and may include a registration card or online form.

The manual will also state the conditions that may void the warranty, such as improper installation, use of non-approved parts, or damage caused by neglect or abuse. Understanding the warranty terms and conditions is essential for protecting your investment and ensuring you receive proper support in case of any issues.

Contact Information

The King 5500 pellet stove manual will provide you with the essential contact information you need for any inquiries or support related to your stove. This contact information will typically include the manufacturer’s address, phone number, and email address.

The manual may also list specific departments or contacts for different types of inquiries, such as technical support, warranty claims, or parts ordering. It is helpful to have this information readily available in case you need to contact the manufacturer for any reason.

In addition to the manufacturer’s contact details, the manual may also include contact information for authorized dealers or service technicians in your area. These local resources can provide valuable assistance with installation, maintenance, and troubleshooting. Having this information at hand can ensure that you get the help you need quickly and efficiently.

Resources

The King 5500 pellet stove manual may provide you with valuable resources to enhance your understanding and experience with your stove. These resources can range from helpful websites and online forums to informative articles and videos.

The manual might direct you to the manufacturer’s website, where you can find product information, user guides, troubleshooting tips, and even parts diagrams. Additionally, you may be referred to online forums dedicated to pellet stove owners, where you can connect with other users, share experiences, and ask questions.

The manual might also list relevant articles or videos that provide insights into pellet stove technology, maintenance practices, or fuel considerations. These resources can help you stay informed and make the most of your King 5500 pellet stove. By accessing these resources, you can gain valuable knowledge and support, ensuring that you have a fulfilling and enjoyable experience with your heating appliance.

The King 5500 pellet stove manual is a valuable resource for owners seeking to maximize their heating experience. It provides a comprehensive guide to installation, operation, maintenance, and troubleshooting, empowering users to confidently and effectively utilize their appliance. By adhering to the safety precautions outlined in the manual and following the recommended maintenance procedures, owners can ensure the longevity and efficiency of their King 5500 pellet stove.

The manual underscores the importance of using high-quality pellet fuel, as recommended by the Association of Pellet Fuel Industries, for optimal performance and reduced emissions. It also emphasizes the need to comply with local building and fire codes for safe and effective installation. By utilizing the resources provided in the manual, owners can enhance their understanding of the stove’s operation and troubleshoot any issues that may arise. In conclusion, the King 5500 pellet stove manual serves as an indispensable tool for owners, providing the necessary information to safely operate and maintain their appliance for years to come.