Virginia Driver’s Manual: A Comprehensive Guide (2026)

Essential for new drivers, this 2026 guide offers detailed insights into Virginia’s traffic laws, regulations, and signs, ensuring confident DMV exam success․

Welcome to the 2026 Virginia Driver’s Manual! This comprehensive guide is meticulously designed to prepare aspiring drivers for safe and responsible operation of a motor vehicle within the Commonwealth of Virginia․ Whether you are a first-time driver, or renewing your license, this manual serves as your primary resource for understanding Virginia’s traffic laws, road signs, and safe driving practices․

The Virginia Department of Motor Vehicles (DMV) regularly updates this manual to reflect changes in legislation and best practices․ The July 1, 2025 edition already incorporates valuable feedback, demonstrating DMV’s commitment to clarity and accuracy․ Mastering the content within will significantly increase your chances of successfully passing the DMV knowledge exam and becoming a licensed Virginia driver․

Understanding the 2025-2026 Updates

The 2025-2026 Virginia Driver’s Manual reflects recent modifications based on valuable input from organizations like the Virginia Bicycle Federation (VBF)․ These updates aim to enhance clarity and address evolving road safety concerns․ Key changes incorporated into the July 1, 2025 edition include revisions to sections on sharing the road with vulnerable users, such as cyclists and pedestrians․

Drivers should familiarize themselves with these updates to ensure compliance with current Virginia traffic laws․ The DMV continually strives to improve the manual, making it a reliable resource for both new and experienced drivers․ Staying informed about these changes is crucial for maintaining a safe driving record and contributing to safer roadways throughout Virginia․

Where to Find the Official Virginia DMV Manual

Accessing the official Virginia DMV Manual is straightforward․ The most reliable source is the Virginia Department of Motor Vehicles (DMV) website․ As of July 1, 2025, the updated edition is readily available for download in a digital format․

Additionally, physical copies of the manual can be obtained at various DMV customer service centers across the state․ Several comprehensive study guides, like those offered by Charis Books and Amazon, also provide access to the manual’s content, often with added practice tests and explanations․ Ensure you are using the most current version to prepare accurately for the DMV exam and drive safely․

Obtaining a Virginia Driver’s License

Successfully navigating the licensing process requires meeting eligibility criteria, completing the GDL program, and providing necessary documentation for application․

Eligibility Requirements for a Virginia Driver’s License

To qualify for a Virginia driver’s license, applicants must meet specific age and residency requirements․ Generally, individuals must be at least 16 years old to obtain a learner’s permit, a crucial first step․ Proof of legal presence in the United States is mandatory, alongside verification of identity and Virginia residency – typically through documents like a birth certificate, social security card, and utility bills․

Furthermore, applicants must demonstrate a basic understanding of traffic laws and safe driving practices, assessed through a knowledge exam․ Those under 18 are required to complete a driver education course approved by the Virginia Department of Education․ Meeting these prerequisites ensures all licensed drivers possess the foundational knowledge and legal standing to operate a vehicle safely on Virginia roadways․

Learner’s Permit: Requirements and Restrictions

Obtaining a Virginia learner’s permit necessitates passing a vision screening and a knowledge exam covering traffic laws and road signs․ Applicants must be at least 15 years and 6 months old․ Once issued, the permit comes with significant restrictions designed to ensure safety during the learning phase; Permit holders must always drive with a licensed driver aged 21 or older in the passenger seat․

Furthermore, there are limitations on driving hours; nighttime driving is generally prohibited unless accompanied by a licensed driving instructor; The learner’s permit is valid for a specific period, typically one year, providing ample time to gain supervised driving experience before attempting the full driver’s license exam․

The Graduated Driver Licensing (GDL) Program

Virginia’s Graduated Driver Licensing (GDL) program is a multi-stage process designed to gradually introduce new drivers to full driving privileges․ It begins with the learner’s permit, followed by a provisional license, and culminates in an unrestricted driver’s license․ The provisional license stage includes restrictions on nighttime driving and passenger numbers, promoting safer driving habits․

Drivers must hold the learner’s permit for a minimum period and complete a certain number of supervised driving hours before qualifying for the provisional license․ Successful completion of each stage demonstrates increasing competence and responsibility, ultimately leading to full driving privileges in Virginia․

Required Documents for License Application

Applying for a Virginia driver’s license requires presenting specific documentation to verify identity, residency, and legal presence in the United States․ Acceptable forms of identification include a certified birth certificate, a valid U․S․ passport, or a permanent resident card․ Proof of Virginia residency, such as a utility bill or lease agreement, is also essential․

Applicants must also provide their Social Security number․ The DMV may require additional documentation depending on individual circumstances․ It’s crucial to check the official Virginia DMV website for the most up-to-date list of acceptable documents before visiting a customer service center․

Virginia Traffic Laws and Regulations

Navigate Virginia roads safely by understanding speed limits, right-of-way rules, and laws concerning alcohol and driving, as detailed in this manual․

Speed Limits in Virginia

Virginia’s speed limits are carefully defined to ensure roadway safety for all users․ Generally, the maximum speed on most rural interstates is 70 mph, while urban interstates typically have a 65 mph limit․ On most highways, the speed limit is 55 mph, though it can vary based on posted signs․ Residential and business districts usually have a speed limit of 25 mph, but this too can be adjusted․

Drivers must always adhere to posted speed limits, as exceeding them significantly increases the risk of accidents․ Remember that speed limits are maximums, and drivers should adjust their speed based on weather conditions, traffic density, and road visibility․ Understanding these regulations, as outlined in the Virginia Driver’s Manual, is crucial for safe and legal driving․

Right-of-Way Rules in Virginia

Understanding right-of-way is paramount for preventing collisions in Virginia․ Generally, vehicles entering a roadway from a private drive or alley must yield to pedestrians and traffic already on the road․ At intersections without traffic signals, drivers must yield to vehicles approaching from the right․

When approaching a stop sign, drivers must come to a complete stop and yield to cross-traffic․ Pedestrians always have the right-of-way in crosswalks, marked or unmarked․ Emergency vehicles with sirens and flashing lights demand immediate right-of-way․ The Virginia Driver’s Manual provides detailed explanations and illustrations of these rules, emphasizing courteous and predictable driving behavior for all road users․

Virginia’s Laws Regarding Alcohol and Driving

Virginia maintains a zero-tolerance policy for drivers under 21 regarding alcohol consumption․ The legal blood alcohol content (BAC) limit for drivers 21 and over is 0․08%․ Refusal to submit to a breath or blood test results in automatic license suspension, independent of BAC results․

Driving under the influence (DUI) carries severe penalties, including fines, jail time, and license revocation․ Virginia also has laws addressing driving while impaired by drugs․ The Virginia Driver’s Manual stresses the dangers of impaired driving and outlines the legal consequences, promoting responsible decision-making and emphasizing the importance of designated drivers or alternative transportation․

Seat Belt Laws and Child Safety Seat Requirements

Virginia law mandates that all drivers and passengers wear seat belts․ Failure to comply results in a monetary fine․ Children under eight years old, or under 57 inches in height, must be properly secured in an approved child safety seat․

The specific type of seat required depends on the child’s age, weight, and height․ Virginia’s DMV provides detailed guidelines on selecting and correctly installing car seats․ Proper usage significantly reduces the risk of injury or fatality in a crash․ The manual emphasizes that child safety seats are not optional, but a legal requirement and a crucial safety measure․

Road Signs and Signals in Virginia

Mastering Virginia’s signs – regulatory, warning, and guide – is crucial for safe navigation and understanding traffic control effectively on all roadways․

Understanding Regulatory Signs

Regulatory signs inform drivers of laws and regulations․ These signs dictate what you must or must not do, and failure to comply can result in fines or legal consequences․ Common examples include speed limit signs, stop signs, yield signs, and do-not-enter signs․

Shapes are key: octagonal signs always indicate stop, triangular signs signify yield, and rectangular signs generally display regulations․ Colors also matter; red often indicates prohibition (like “Do Not Enter”), while white displays regulations․ Recognizing these visual cues instantly is vital for safe driving․

Pay close attention to any additional text or symbols on the sign, as they provide specific instructions․ Understanding these signs is fundamental to navigating Virginia roads legally and safely․

Warning Signs and Their Meanings

Warning signs alert drivers to potentially hazardous conditions ahead․ Typically yellow and diamond-shaped, these signs don’t prohibit action but advise caution․ They prepare you for unexpected situations like curves, intersections, pedestrian crossings, or changes in road conditions․

Symbols on warning signs are standardized to be universally understood; A sign depicting deer indicates a high probability of deer crossing the roadway․ Similarly, a winding road sign warns of upcoming curves․ Recognizing these symbols quickly is crucial for reacting appropriately․

Reduce speed and increase awareness when encountering warning signs․ Be prepared to brake, steer, or take other evasive actions as needed to maintain safety․ Ignoring these warnings can lead to accidents․

Guide Signs: Navigating Virginia Roads

Guide signs provide motorists with essential information for navigation․ Predominantly green or blue, these signs offer directions to destinations, distances to cities, and points of interest․ They help drivers plan routes and stay on course efficiently․

Interstate and U․S․ route markers fall under guide signs, utilizing distinct shield shapes and numbering systems․ State route markers, often rectangular, indicate roads maintained by the Commonwealth of Virginia․ Destination signs list upcoming exits and their corresponding cities or towns․

Pay close attention to guide signs, especially when traveling long distances or in unfamiliar areas․ They are designed to minimize confusion and ensure a smooth, safe journey throughout Virginia’s extensive road network․

Traffic Signal Interpretation

Understanding traffic signals is crucial for safe driving in Virginia․ Solid red signifies a complete stop before the marked stop line․ A yellow light indicates the signal is changing to red, requiring drivers to stop if safe; proceeding with caution is permitted otherwise․

Green lights allow drivers to proceed, unless encountering conflicting traffic․ Flashing red functions as a stop sign, while flashing yellow demands caution․ Green arrows permit turns in the indicated direction, while yellow arrows signal the protected turn is ending․

Always be aware of pedestrian signals and yield accordingly․ Improperly interpreting signals is a leading cause of accidents; prioritize attentiveness and adherence to signal indications․

Preparing for the Virginia DMV Exam

Ace your test with practice questions, study resources, and by avoiding common mistakes – mastering the Virginia DMV scoring system is key!

Sample Knowledge Exam Questions

Prepare effectively by reviewing sample questions mirroring the Virginia DMV exam’s format․ These questions cover crucial topics like right-of-way rules, speed limits, and safe driving practices․ Expect inquiries about regulatory, warning, and guide signs, demanding a thorough understanding of their meanings․

Practice interpreting traffic signals and recognizing scenarios requiring defensive driving techniques․ Familiarize yourself with Virginia’s laws concerning alcohol and driving, seat belt usage, and child safety seat requirements․

Numerous resources offer practice tests – utilize them! Understanding the nuances of Virginia’s traffic regulations is paramount for passing the knowledge exam and becoming a safe, responsible driver on Virginia roads․ Consistent study and practice are vital for success․

Practice Tests and Study Resources

Maximize your preparation with readily available practice tests designed to simulate the Virginia DMV knowledge exam․ Several online platforms and publications, like those offering 360 driving test questions, provide comprehensive assessments․ These resources are invaluable for identifying knowledge gaps and reinforcing key concepts from the official Virginia Driver’s Manual․

Look for study guides that include detailed explanations for both correct and incorrect answers, enhancing your understanding of traffic laws and regulations․

Remember to utilize the official DMV website for the most up-to-date information and resources․ Consistent practice and a focused study approach are crucial for achieving a passing score on the exam and ensuring safe driving habits․

Common Mistakes to Avoid on the DMV Exam

Many candidates stumble on questions regarding right-of-way rules, speed limits in different zones, and proper responses to various traffic signals․ Misinterpreting warning signs and regulatory signs is also a frequent error․ Carefully read each question and all answer choices before selecting your response; rushing often leads to careless mistakes․

Don’t assume your intuition is correct – always refer back to the information presented in the official Virginia Driver’s Manual․

Pay close attention to questions involving alcohol and driving laws, as well as seat belt and child safety seat requirements․ Thorough preparation and a calm demeanor are key to avoiding these common pitfalls․

Understanding the Virginia DMV Scoring System

The Virginia DMV knowledge exam requires a passing score to obtain your learner’s permit or driver’s license․ While the exact passing score isn’t publicly detailed, generally, you need to answer at least 80% of the questions correctly․ Each question is worth one point, and incorrect answers do not incur negative marking․

Focus on mastering the material presented in the official Virginia Driver’s Manual, as the exam questions are directly based on this content․

Practice tests are invaluable for familiarizing yourself with the question format and identifying areas where you need further study․ Aim for consistent high scores on practice exams to build confidence․

Safe Driving Practices in Virginia

Prioritize defensive driving, be aware of surroundings, and share roads respectfully with all users—motorcycles, bicycles, and pedestrians—for Virginia safety․

Defensive Driving Techniques

Mastering defensive driving is crucial for Virginia roadways․ Anticipate potential hazards by scanning the road ahead, checking mirrors frequently, and maintaining a safe following distance․ Always be prepared to react to unexpected situations, like sudden stops or lane changes․

Avoid distractions – put away phones, adjust music before driving, and minimize conversations․ Recognize and manage your emotions; aggressive driving significantly increases risk․ Be aware of other drivers’ behaviors and adjust your driving accordingly․

Understanding blind spots and utilizing proper signaling are vital․ Remember, defensive driving isn’t about avoiding accidents entirely, but minimizing their severity if they occur․ Prioritize safety and remain vigilant at all times․

Sharing the Road with Motorcycles and Bicycles

Virginia drivers must exercise extra caution around motorcycles and bicycles․ Motorcycles are smaller and harder to see; always check blind spots and allow ample following distance․ Be aware that motorcycles can stop much faster than cars․

Bicyclists have the same rights and responsibilities as other vehicles․ Give them at least three feet of clearance when passing, and be mindful of turning movements․ Watch for cyclists when making right turns, a common collision point․

Increased awareness and respectful behavior are key․ Never assume a motorcyclist or cyclist sees you․ Prioritize their safety and share the road responsibly, contributing to a safer environment for everyone․

Driving in Adverse Weather Conditions

Virginia experiences varied weather, demanding adjusted driving techniques․ In rain, reduce speed and increase following distance to compensate for reduced traction and visibility․ Activate headlights to enhance visibility to others․

During snow or ice, drive slowly and cautiously․ Avoid sudden braking or steering maneuvers․ Be prepared for longer stopping distances․ If conditions become too hazardous, pull over to a safe location․

Fog requires slow speeds, low-beam headlights, and potentially fog lights․ Never use high beams in fog, as they reflect back and worsen visibility․ Always prioritize safety and adjust driving to match the prevailing weather conditions․

Distracted Driving and its Dangers

Distracted driving is a major safety concern in Virginia․ It encompasses anything that takes your attention away from the primary task of driving – visual, manual, and cognitive distractions․

Texting while driving is illegal and particularly dangerous, significantly increasing crash risk․ Even hands-free devices can be distracting․ Avoid using cell phones, adjusting the radio, or engaging in complex conversations while operating a vehicle․

Focus solely on driving․ Prioritize road awareness and anticipate potential hazards․ Recognize that even brief distractions can have devastating consequences․ Safe driving demands your full and undivided attention at all times․

Vehicle Registration and Insurance

Virginia requires vehicle registration and minimum insurance coverage for all drivers, ensuring financial responsibility and legal operation on roadways․

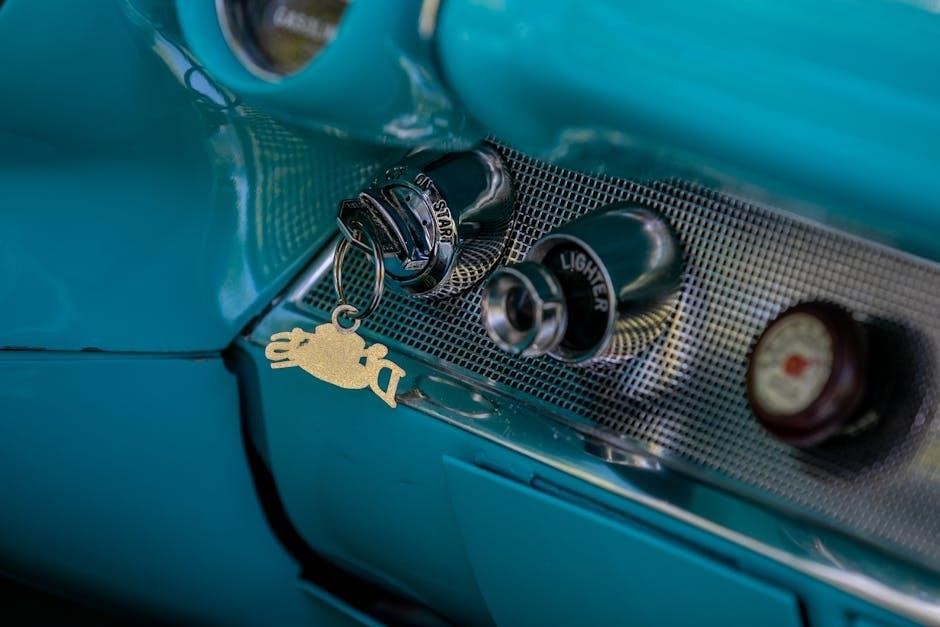

Virginia Vehicle Registration Requirements

Registering your vehicle in Virginia is crucial for legal operation․ New residents have 30 days to obtain a Virginia registration and driver’s license․ Required documents typically include proof of identity, proof of Virginia residency, the vehicle’s title, and a completed application form (VSA 17A)․

Vehicle inspections are mandatory annually, ensuring safety standards are met․ Registration fees vary based on the vehicle’s weight and age․ You can register your vehicle online, by mail, or in person at a DMV customer service center․ Proper registration avoids penalties and ensures compliance with Virginia law, contributing to safer roads for everyone․

Minimum Insurance Coverage in Virginia

Virginia law mandates minimum liability insurance coverage for all registered vehicles․ Currently, the minimum requirements are $25,000 for injury or death of one person, $50,000 for injury or death of two or more persons, and $20,000 for property damage․

Drivers must present proof of insurance when registering their vehicles and upon request by law enforcement․ Uninsured motorist coverage is also available, protecting drivers in case of accidents with uninsured individuals․ Maintaining adequate insurance coverage is essential for financial protection and legal compliance, ensuring responsible driving within the Commonwealth․

Understanding Virginia’s Uninsured Motorist Laws

Virginia’s uninsured motorist (UM) laws provide crucial protection when you’re involved in an accident with a driver lacking insurance․ UM coverage can compensate for your bodily injuries and, in some cases, property damage․ You can choose to reject UM coverage in writing, but this is generally not advised․

There are two types: Uninsured Motorist Bodily Injury (UMBI) and Uninsured Motorist Property Damage (UMPD)․ Understanding these laws is vital, as they safeguard your financial well-being after an accident caused by an irresponsible, uninsured driver․ It’s a key component of responsible vehicle ownership in Virginia․